Electronic design

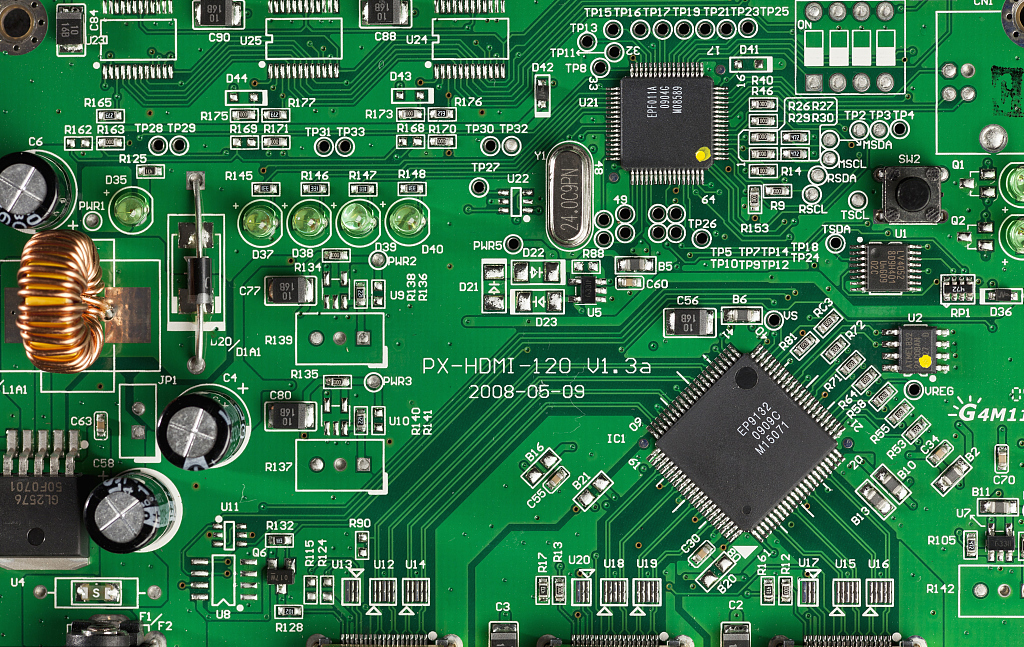

At DSC, we have extensive experience in electronic design, including schematic design, PCBA layout, PCBA prototype. We work closely with our clients to understand their unique needs and develop customized electronic solutions that meet their specifications.

HARDWARE DEVELOPMENT

Experienced electronic design engineers in our team has a deep understanding of the latest industry standards and technologies, and we use the latest design tools and software to ensure that our designs are accurate, reliable, and efficient. We also have a proven track record of delivering high-quality electronic designs on time and within budget.

◼ Powe supply: DCDC and LDO power supply.

◼ Signal conditioning circuit.

◼ Sensors, including thermopiles, optical sensors, temperature probes, and pressure gauges.

◼ Control circuit with MCU: ST, Nuvoton, MicroChip…

◼ Skilled in designing 1-8 layers PCBs.

◼ Experienced in design high-power LEDs using AL-base PCB.

◼ EMC, ESD, RF433, WIFI module for compance

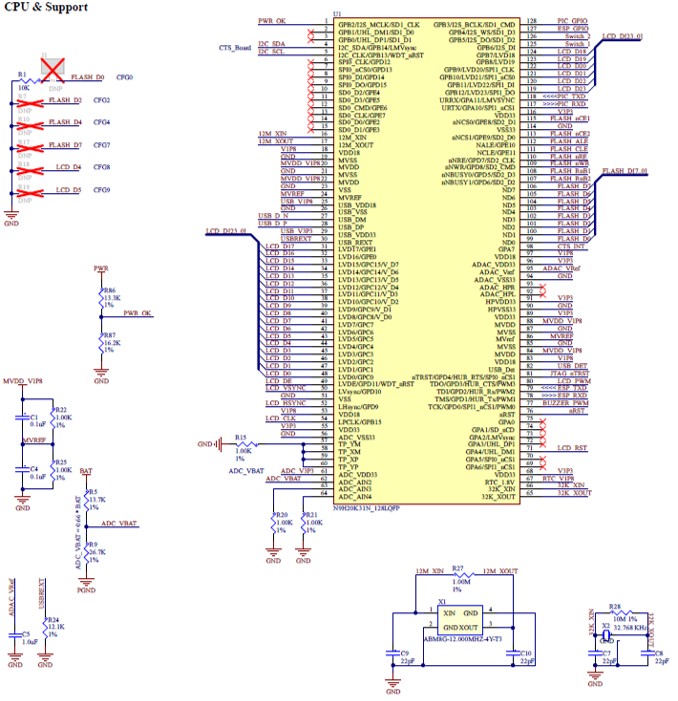

Schematic Design

Schematic design is an essential part of the hardware design process for printed circuit board assemblies (PCBAs). It involves creating a graphical representation of the circuitry that will be included in the PCBA. The schematic captures the electrical connections between the components and defines the overall architecture of the PCBA.

Schematic Design Services

Advantages

DSC schematic design services offer several advantages to clients seeking high-quality PCBAs.

Quality

Our team is committed to delivering high-quality schematics that are optimized for performance, reliability, and cost-effectiveness. We have rigorous quality assurance process in place to ensure that our schematics meet the highest standards.

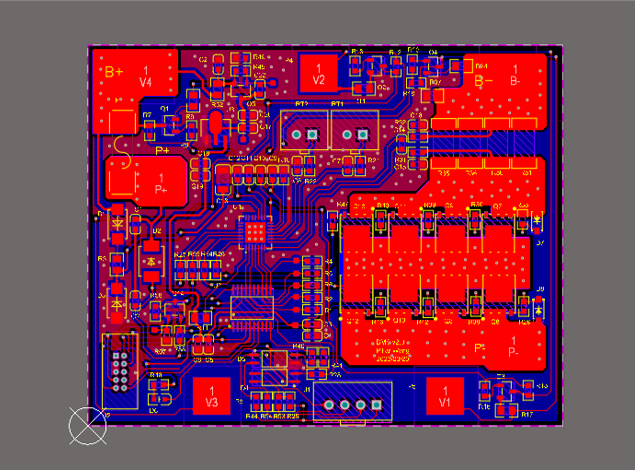

PCB Layout

PCB layout is the process of designing the physical layout of electronic components, connectors, and circuitry on a board. The layout must consider the electrical and mechanical requirements of the circuit and the board’s manufacturing constraints. PCBA layout is a critical step in the overall design process, as well-designed layout can improve circuit performance and reduce manufacturing cost.

DSC team has extensive experience in PCB layout design and can create layouts for a range of applications, from simple to complex. We can design single-sided and double-sided PCBs, multi-layer PCBs up to 8 layers, flexible PCBs, and aluminum base PCBs. Our team also considers EMI and EMC problems during the design process, ensuring that the board meets industry standards for electromagnetic compatibility.

In addition, we have the expertise to optimize signal routing, minimize noise, and avoid signal/power issues that can impact circuit performance. With our comprehensive knowledge of PCB design software, we can create layouts quickly and accurately, reducing the time and cost associated with the design process. Our goal is to create PCB layouts that are not only functional and reliable but also cost-effective and manufacturable.

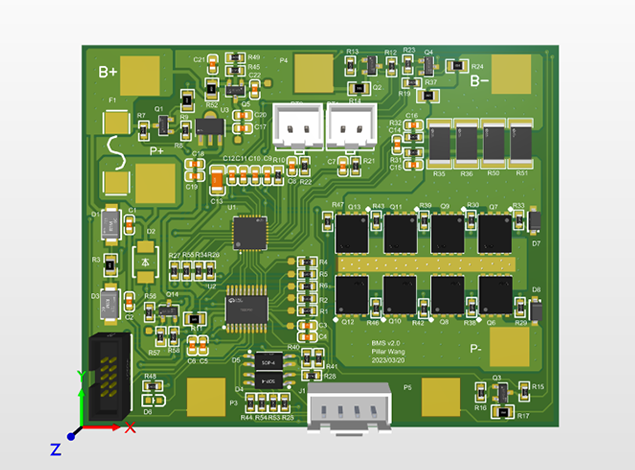

PCBA prototyping and validation

PCBA prototyping is the final stage of the hardware design process, where a physical prototype of the circuit board is produced to verify its functionality and performance. This involves assembling electronic components onto the fabricated PCB and testing its functionality.

In addition, we work closely with our clients throughout the prototyping process, providing regular updates and feedback to ensure that the prototype meets their requirements. Our goal is to deliver prototypes that are not only functional and reliable but also scalable and manufacturable. By using our China supplier chain, we can also reduce lead times and production costs, allowing our clients to bring their products to market faster and more cost-effectively.